How Automated Barcode Repair Reduces Shipping Error?

In today’s fast-paced logistics and e-commerce environment, speed and accuracy are critical. A single unreadable or damaged barcode can disrupt the entire shipping process, leading to delayed deliveries, lost packages, and unhappy customers. Fortunately, automated barcode repair systems are transforming the way companies handle these issues, improving efficiency and reducing costly errors.

The Problem with Damaged Barcodes

Barcodes are the backbone of modern shipping operations. They track packages through warehouses, trucks, and distribution centers. However, barcodes are often exposed to wear and tear. Labels can be scratched, smudged, or partially torn, making them unreadable by scanners.

Traditionally, human intervention was required to manually verify and correct these barcodes, causing delays and increasing the chance of human error. In large-scale operations, even a small error can cascade into major issues, such as misrouted shipments or inventory discrepancies.

How Automated Barcode Repair Works

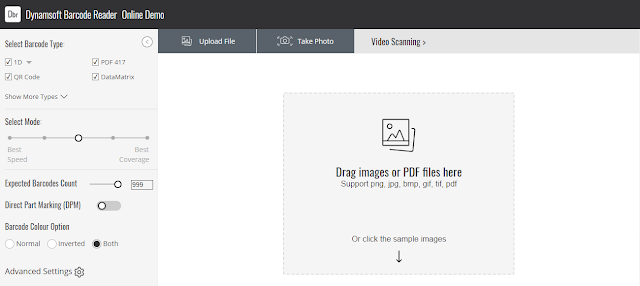

Automated barcode repair leverages advanced scanning algorithms and AI to detect damaged or unreadable barcodes in real time. Once detected, the system can:

-

Reconstruct missing or corrupted parts of the barcode.

-

Correct scanning errors caused by smudges, distortion, or poor printing.

-

Integrate with warehouse management systems to update inventory and shipping records immediately.

Some systems even predict common barcode errors based on historical data, allowing the system to proactively repair or alert staff before shipments are delayed.

Benefits of Automated Barcode Repair

-

Reduced Shipping Errors: Corrected barcodes prevent misrouted packages and ensure the right item reaches the right customer.

-

Faster Processing: Real-time repair eliminates the need for manual checks, speeding up warehouse throughput.

-

Cost Savings: Fewer shipping errors mean less product loss, fewer returns, and reduced labor costs.

-

Improved Customer Experience: Accurate and timely deliveries lead to happier customers and repeat business.

-

Enhanced Inventory Accuracy: Automated repairs keep inventory data synchronized across all systems.

Real-World Use Case

Consider a large e-commerce warehouse handling thousands of packages daily. With manual barcode verification, damaged labels often caused delays in shipping and incorrect orders. After implementing an automated barcode repair system, the warehouse experienced a 40% reduction in scanning errors and faster order fulfillment. Customers received orders on time, and operational efficiency improved significantly.

Conclusion

Automated barcode repair is more than just a technological upgrade—it’s a critical tool for error-free shipping and efficient supply chain management. By detecting and correcting damaged barcodes in real time, businesses can reduce shipping errors, save costs, and deliver a better experience to their customers.

Comments

Post a Comment